Choosing the right Differential Scanning Calorimeter for your job is important. We understand this - there are so many types of DSC instruments on the market. How do you begin to choose?

This isn't just another generic buyer's guide - it's the kind of practical advice we'd like to have when buying a DSC for the first time.

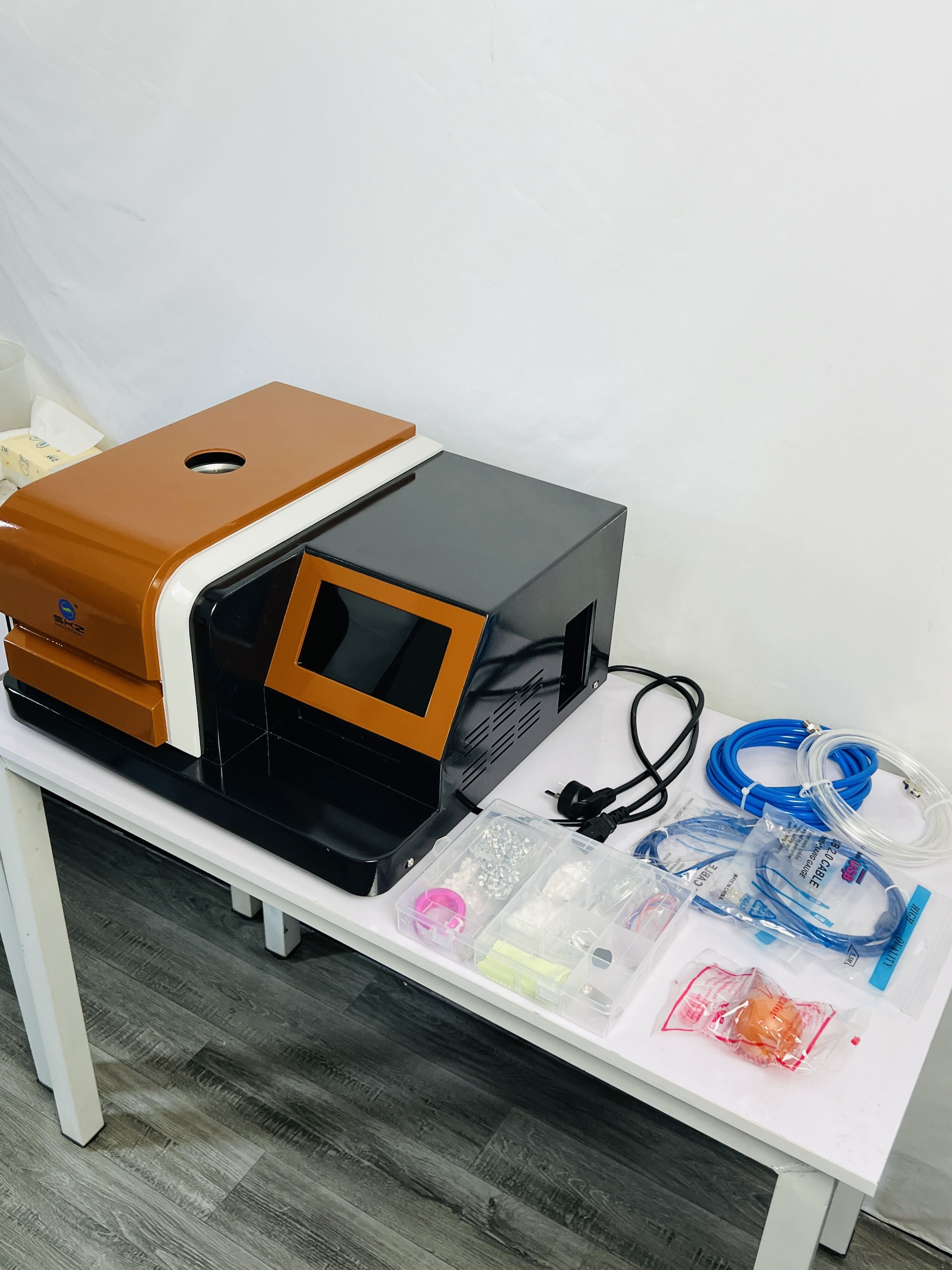

1. Understanding Differential Scanning Calorimeters

Differential Scanning Calorimetry measures the heat flow of a material as it undergoes a phase change, chemical reaction or thermal decomposition. It is widely used:

Polymer science (glass transition, crystallization)

Pharmaceuticals (drug stability, purity testing)

Metallurgy (alloy behavior, melting points)

Food science (fat content, shelf-life studies)

Types of DSC Instruments

Heat Flux DSC – Cost-effective, great for routine analysis

Power Compensation DSC – Higher sensitivity, ideal for precise measurements

Modulated DSC (MDSC) – Separates reversible and non-reversible heat flow

2. Key Factors to Consider When Choosing a DSC

A. Temperature Range and Heating Rate

Typically, the temperature ranges from -150°C to 600°C (which covers most application needs).

[Extended range] includes materials up to 1600°C but is typically only a need for more unusual materials.

Heating/cooling rates: While faster heating/cooling rates (e.g. 100°C/min) can improve throughput, they can lead to loss of resolution.

B. Sensitivity and Detection Limits

High sensitivity is essential for detecting weak transitions (e.g. glass transitions in thin films). Ensure to have very low noise levels (<1 µW) to ensure accuracy.

C. Sample Capacity and Atmosphere Control

Types of pans: Standard; high pressure; European pans; hermetic, for example; The latter is important for reactivity reasons.

Types of gasses: There can be inert (e.g. N₂); oxidizing (air); or reactive possibilities (e.g. H₂).

D. Software and Data Analysis

Be able to use a simple interface. Consider systems that automate peak pickers and do comprehensive peak analysis.

Make sure the system complies with ISO, ASTM or USP requirements.

Export options (e.g. Excel & PDF, LIMS) are also important.

E. Maintenance costs such as calibration, consumables and service contracts should also be considered.

3. Maintenance & Best Practices

To ensure long-term accuracy, follow these tips:

✔ Regular calibration (yearly or per usage intensity)

✔ Clean furnace & sensors to prevent contamination

✔ Use proper sample prep (correct pan type, sample weight)

✔ Update software for improved features and bug fixes

4.Final Checklist Before Buying

Before purchasing a differential scanning calorimeter, please consider the following:

a. Does the instrument provide the temperature range of interest?

b. Is the sensitivity appropriate for my sample types?

c. Does the software have the specifications I require to analyze my data?

d. What support is there after the instrument is purchased?

e. Are there additional costs I might not know about (example: maintenance & consumables)?

Conclusion

Choosing the right Differential Scanning Calorimeter (DSC) is purely a function of application, budget, and resolution. Then when you factor specifications, like temperature range, sensitivity, and/or software, there will be a large range of possible DSCs for your lab.

Not sure what to select? Don't hesitate to contact one of our thermal analysis experts for tailored advice!